How to Strip a Starter Motor for Maintenance and Repair

How to Strip a Starter Motor for Maintenance and Repair

Engaging in the process of taking apart a vital automotive component can be both a rewarding and enlightening experience. Understanding the intricacies of this mechanism not only enhances your technical skills, but also deepens your appreciation for automotive engineering. This section will walk you through the essential steps involved in carefully dismantling this powerful unit, ensuring that you gain both knowledge and confidence.

Throughout this exploration, you’ll uncover the necessary tools and techniques to complete the task successfully. By following precise instructions, you will learn how to identify various elements within the assembly, enabling you to conduct thorough inspections and potential reinvestment into the unit’s functionality. Each phase of disassembly will be illustrated, guiding you through the entire procedure with ease.

Whether you are a seasoned mechanic or a novice enthusiast, this resource serves as your companion. With diligence and attention to detail, the journey of unraveling the complexities of this indispensable device awaits you, promising insights that can fuel your passion for automotive repair and maintenance.

Understanding the Starter Motor Functionality

This section delves into the vital role played by a crucial component in the ignition process of an automobile. It engages with the mechanisms that enable a vehicle to initiate operation and provides insights into how this assembly works in tandem with other systems.

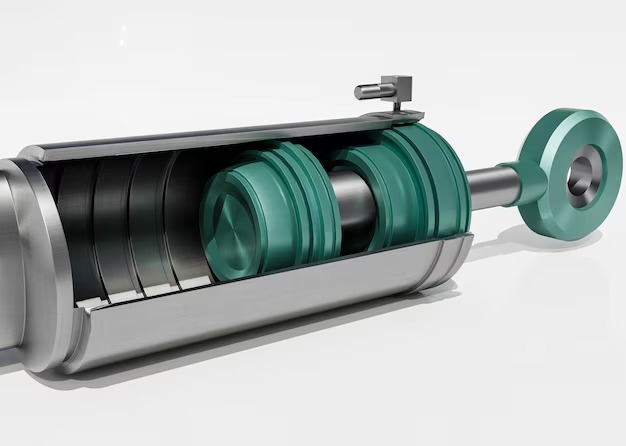

Key Components and Their Roles

- Electric Coil: Generates a magnetic field when current flows through it, essential for functioning.

- Gear Reduction: Enhances torque, allowing the engine to turn over effortlessly.

- Solenoid: Acts as a switch that engages and disengages the mechanism depending on the ignition status.

- Armature: Connects to the flywheel and is responsible for initiating the crankshaft’s rotation.

The Process of Engagement

The engagement begins when the ignition key is turned, sending a signal to activate the solenoid. This action results in:

- The energizing of the coil.

- The solenoid pushing the pinion gear into mesh with the flywheel.

- The rotation of the armature, which subsequently turns the engine over.

Once the engine starts running, the solenoid disengages, allowing the gear to retract, thus preventing damage to the components. Understanding this cycle is crucial for diagnosing potential issues.

Tools Required for Disassembly

Prior to embarking on the task at hand, it’s essential to gather a selection of equipment that will facilitate efficient dismantling. Having the appropriate instruments not only streamlines the process but also ensures safety and reduces the risk of damaging components.

Begin with basic hand tools such as a set of sockets and ratchets of various sizes, as well as wrenches to access different fasteners. Additionally, a screwdriver set with assorted tips will prove invaluable for removing any screws that hold parts in place. Pliers, especially needle-nose types, can aid in gripping and manipulating small components.

Consider including specialized tools designed for automotive applications. A torque wrench is crucial for reassembly, ensuring that all fasteners are tightened to the manufacturer’s specifications. Magnetic trays can help keep small hardware organized, while a workbench with adequate lighting will enhance visibility and ease of access to tools.

Lastly, safety gear should not be overlooked. Gloves protect your hands from sharp edges, while safety glasses shield your eyes from debris. Collecting these tools in advance will prepare you for a successful and efficient disassembly process.

Step-by-Step Disassembly Process

In this section, we will delve into the meticulous procedure required to take apart a crucial component of your vehicle’s ignition system. Understanding the methodical approach to disassembly will ensure you grasp the inner workings and maintain your equipment effectively.

Preparation Phase

Before commencing the dismantling journey, gather all necessary tools such as wrenches, screwdrivers, and pliers. It’s also essential to create a clean workspace free from distractions. Ensuring that the power source is disconnected will prevent any accidental damage or injury during the process. Having a reference for reassembly can be quite beneficial.

Disassembly Steps

Begin by removing any outer coverings or casings that shield the inner parts. Carefully detach electrical connections while noting their positions, as this will aid in reassembly. Next, systematically unscrew and take off each internal component, such as the solenoid and armature, while maintaining an organized approach to prevent loss of parts. Pay attention to the orientation of each piece to facilitate proper reinstallation later.

As you work through the components, clean each part and inspect for signs of wear or damage. This practice not only prepares the components for maintenance but also enhances longevity. Thoroughly documenting your process using notes or pictures can simplify the overall reassembly and troubleshooting when necessary.

Common Issues with Starter Motors

Many vehicle owners encounter various challenges related to the initial power mechanism. Identifying these problems early can save time, money, and frustration. Understanding the typical malfunctions that may arise is essential for effective maintenance and timely repairs.

Electrical Failures are among the most frequent complications. Issues such as faulty wiring or a weakened battery can prevent the device from functioning correctly. A worn-out solenoid might also contribute to power loss, leading to a complete inability to start the engine.

Mechanical Problems may arise due to wear and tear over time. Components such as bearings, gears, and brushes can deteriorate, causing strange noises or failure to engage. If the internal parts are damaged or misaligned, they can significantly impact overall performance.

Corrosion can be a hidden culprit that affects operation. Moisture exposure can lead to rust forming on terminals, connectors, and within the electrical system. This buildup may hinder connectivity and reduce the efficiency of the component.

Heat Damage is another issue that affects functionality. High temperatures can cause components to expand, leading to warping or damage. Continual overheating can ultimately shorten the lifespan of the part, resulting in premature failure.

Addressing these typical concerns promptly is vital for optimal performance. Regular inspections and maintenance can help in identifying potential threats and ensuring the reliable operation of the starting system.

Cleaning and Maintenance Tips

Maintaining optimal performance of crucial components is essential for ensuring longevity and reliability. Regular upkeep not only enhances functionality but also prevents unexpected failures. Following a systematic approach to cleaning and care will significantly improve the lifespan of these vital elements.

Regular Inspection

Routine checks are vital for identifying potential issues before they escalate. During each examination, look for signs of dirt accumulation, corrosion, or loose connections. If grime is present, it’s best to address it promptly to avoid more serious problems down the line.

Appropriate Cleaning Techniques

When embarking on a cleaning session, utilize non-corrosive, gentle solutions that will not harm surfaces. Always ensure that all electrical connections are thoroughly dried after cleaning, as moisture can lead to malfunctions. Use a soft brush or cloth to remove contaminants from intricate parts, and avoid excessive force that could cause damage. Regularly applying a light lubricant can also protect against rust and ensure smooth operation.

Reassembling the Starter Motor Correctly

Putting components back together requires precision and attention to detail. Each piece plays a significant role in ensuring the overall functionality and reliability of the assembly. This phase is critical, as improper installation can lead to failures or performance issues down the line.

Essential Steps to Follow

When returning parts to their original configuration, it’s important to follow systematic steps. This method minimizes errors and enhances the efficiency of the entire process. Consider these key actions:

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools for reassembly. |

| 2 | Begin with the housing, ensuring it is clean and free from debris. |

| 3 | Carefully install brushes and springs, confirming they are positioned correctly. |

| 4 | Attach the armature, ensuring it is aligned with precision. |

| 5 | Install the end plate, securing it firmly without over-tightening. |

Tips for Successful Reassembly

To further enhance the reliability of your work, keep in mind the following advice. Using a methodical approach is key to a successful assembly, and these pointers can help guide you:

- Inspect each part for wear and damage before reassembly.

- Consult the service manual for torque specifications and wiring diagrams.

- Take your time and do not rush the process to avoid mistakes.

- Double-check all connections to ensure a proper fit.

- Test functionality once reassembled, prior to final installation.

Q&A: Stripping the starter motor

How do I replace the starter on my vehicle?

To replace the starter on your vehicle, first, disconnect the battery to prevent any electrical shorts. Then, locate the starter, which is typically mounted near the engine block. Remove any components obstructing access, and unbolt the starter from its mounting. Finally, install the new starter by reversing the removal process.

What steps should I take to remove the starter from my car?

To remove the starter from your car, begin by disconnecting the negative battery cable. Next, locate the starter and take note of its mounting bolts. Carefully unbolt the starter from the engine, ensuring you also disconnect any electrical connections. Once free, you can remove the starter from its position.

How can I ensure my engine will crank after replacing the starter?

After replacing the starter, you can ensure your engine will crank by double-checking all electrical connections and ensuring they are secure. Reconnect the battery and try to start the engine. If everything is properly installed, the engine should crank without issues.

What tools do I need to remove the starter from a vehicle?

To remove the starter from a vehicle, you will typically need a socket set, wrenches, and possibly a ratchet extension for hard-to-reach bolts. A multimeter can also be helpful for checking electrical connections before and after removal.

Is it necessary to remove any components to access the starter?

Yes, it is often necessary to remove certain components to access the starter, especially if it is located in a tight space. This may include removing heat shields, air intake parts, or other accessories that obstruct access to the starter.

What should I check if my engine cranks but does not start after replacing the starter?

If your engine cranks but does not start after replacing the starter, check for proper fuel delivery, spark at the spark plugs, and ensure that all electrical connections are secure. Additionally, verify that the replacement starter is functioning correctly.

Can a faulty shaft affect the performance of my starter?

Yes, a faulty shaft can affect the performance of your starter. If the shaft is damaged or misaligned, it may prevent the starter from engaging properly with the flywheel, leading to starting issues or failure to crank.

How do I know if I need to replace my starter or just remove it for inspection?

If your vehicle struggles to crank or makes a clicking noise when attempting to start, it may indicate a faulty starter. Removing it for inspection can help determine if it needs replacement or if there are other underlying issues affecting its operation.

What safety precautions should I take when removing the starter?

When removing the starter, always disconnect the battery first to avoid electric shocks. Wear safety goggles and gloves to protect yourself from debris and sharp edges. Ensure that your vehicle is securely lifted if you need to work underneath it.

Can I replace the starter myself or should I hire a professional?

You can replace the starter yourself if you have basic mechanical skills and tools. However, if you’re unsure about any steps or lack experience, hiring a professional mechanic is advisable to ensure proper installation and avoid potential damage.

To replace the starter on your vehicle, what is the first step you’ll need to take?

The first step you’ll need to take is to disconnect the negative battery cable to ensure safety while working on the electrical components.

What should you do after disconnecting the battery’s negative cable?

After disconnecting the battery’s negative cable, you should lift the hood and locate the starter, which is usually near the bell housing of the engine.

How can you determine if the starter is faulty before replacing it?

You can check the battery with a tester to ensure it has around 12.6 volts. If the battery is good, you can then bench test the starter to see if it spins properly.

What are some general steps to follow when removing the old starter?

Some general steps include removing any components that need to be removed for access, unbolting the starter bolts, and disconnecting the battery cable and other electrical connections.

When purchasing a new starter motor, what should you consider?

When you purchase a new starter motor, consider checking online marketplaces like eBay for competitive prices and ensure that it matches your vehicle’s specifications.

What should you do with the old one after installing a new starter?

After installing a new starter, it’s best practice to wipe it down and clean any mess caused during the replacement process before disposing of the old one properly.

How can grease affect the performance of a new starter?

Grease can help lubricate moving parts inside the starter, but too much grease can cause issues. Ensure that only necessary parts are greased, such as the end cap and bearings.

What is one common cause of a starter failing?

One common cause that leads to a starter failing is corroded connections or wires, which can prevent adequate power from reaching the starter motor.

If unsure about your ability to replace the starter, what should you do?

If you’re unsure about replacing the starter yourself, it may be beneficial to consult resources like Quora for advice or hire a professional mechanic to tackle the job.

What should you also check when replacing a starter regarding other components?

When replacing a starter, also check the alternator and ensure that all sensors and holders are in good condition to avoid further issues down the line.