How to Replace a Water Pump Yourself

How to Replace a Water Pump Yourself

Ensuring optimal performance of your vehicle involves various maintenance tasks, one of which is examining and swapping out key components in the circulation system. This vital procedure helps to maintain the overall health of the engine, promoting longevity and efficiency. A thorough understanding of the intricacies involved can save both time and resources in the long run.

In this informative piece, we will delve into the process of tackling this crucial task, highlighting necessary tools, techniques, and precautions. Whether you’re an experienced mechanic or a novice enthusiast, you’ll find valuable insights that cater to different skill levels while emphasizing safety and effectiveness throughout.

Let’s embark on this journey to demystify the essentials of maintaining your vehicle’s cooling efficiency. By following the outlined methods, you can ensure that your engine remains in peak condition, reducing the likelihood of costly repairs and enhancing your driving experience.

Essential Tools for Water Pump Replacement

Successfully completing a project of this nature requires a selection of fundamental equipment. Gathering the necessary instruments in advance can greatly enhance efficiency and ensure a smooth workflow. Having the right tools not only simplifies the task but also minimizes the risk of errors during the process.

Basic Hand Tools

A variety of hand tools forms the backbone of this undertaking. Wrenches, screwdrivers, pliers, and socket sets are critical for loosening and securing fittings. Additionally, a good pair of gloves can protect your hands while providing a better grip on potentially slippery surfaces.

Specialized Equipment

In addition to regular hand tools, some specialized instruments may be needed. A torque wrench is essential for applying the correct tightness to fasteners, preventing damage. Consider including a gasket scraper and a drain pan in your toolkit to ensure a clean and efficient process. Lastly, a reliable flashlight will come in handy when working in dimly lit areas.

Signs Your Water Pump Needs Replacing

Identifying the need for a new asset can prevent further complications and costly repairs. Various indicators may signal that your malfunctioning unit cannot perform its intended function effectively. Recognizing these signs early can help maintain the efficiency of your entire system.

One common symptom is an unusual noise, such as grinding or whining, that differs from the normal operation sounds. Additionally, frequent overheating or an increase in temperature may indicate an underlying issue with the equipment. Leaks around the designated area should not be overlooked, as they commonly suggest deterioration or damage.

Inconsistencies in performance, like poor flow or pressure, can also serve as red flags. Diminished output may signify an internal problem, making it essential to evaluate the situation promptly. Lastly, any visible corrosion or wear should be taken seriously, as it often points to the necessity for a replacement.

Step-by-Step Disassembly Process Explained

This section outlines the intricate procedure to methodically take apart the unit, ensuring that each component is handled with care. By following a clear sequence, one can easily navigate through the dismantling process, minimizing the risk of damage and facilitating smoother reassembly.

- Gather Necessary Tools:

Before initiating, collect essential equipment including wrenches, screwdrivers, and pliers.

- Disconnect Power Supply:

Ensure safety by disconnecting the electrical source to prevent any accidental activation.

- Access the Housing:

Remove any outer coverings or panels that provide access to the internal components. This may involve unscrewing bolts or unclipping secured sections.

- Loosen Fasteners:

Systematically unfasten screws or bolts that secure various parts. Keep track of each fastener for easier reassembly.

- Detaching Elements:

Carefully separate connected components such as hoses and wiring. Pay attention to their positions for subsequent reinstatement.

- Remove Central Component:

Once all attachments are undone, gently take out the core part of the assembly, ensuring not to apply excessive force.

Following this organized method not only enhances efficiency but also reduces the likelihood of errors during the disassembly process. Proper documentation of each step can prove invaluable when the time comes to reassemble the system.

Installing the New Water Pump Safely

Securing the installation of new components is crucial for optimal performance and longevity. Adhering to safety protocols ensures not only the integrity of the system but also the well-being of the individual undertaking the task. Precautionary measures reduce the risk of accidents and guarantee a successful operation.

Begin by ensuring the workspace is clean and organized. Remove any debris or tools that may obstruct movement or create hazards. It is essential to have proper lighting and ventilation, especially if working in enclosed spaces. Before proceeding, confirm that all necessary equipment is on hand to avoid interruptions.

When handling parts, wear suitable protective gear such as gloves and safety glasses. This minimizes exposure to harmful substances and protects against potential injuries. Be mindful of sharp edges and moving elements throughout the process. Following these safety tips mitigates risks significantly.

Prior to installation, carefully examine all components for damage or irregularities. Ensure the new item fits correctly within the designated area and verify that all accompanying seals and gaskets are in good condition. Proper alignment and secure fastening are vital to prevent leaks and operational issues.

Once installed, double-check all connections and ensure that everything is tightly secured. It’s a good practice to test the system before fully reassembling any surrounding elements. This allows for adjustments without complications. Following these guidelines will help maintain a safe environment while achieving efficient functionality.

Common Mistakes to Avoid When Replacing

When embarking on a task involving component substitution, it is critical to be aware of potential pitfalls that can complicate the process. Understanding common missteps can save time, prevent damage, and ensure a successful result. Here, we outline key errors to sidestep for a smoother experience.

1. Ignoring Manufacturer Specifications

One prevalent error is neglecting the guidelines provided by the manufacturer. Each model may have specific requirements, and overlooking these can lead to compatibility issues or suboptimal performance.

2. Using Incorrect Tools

Utilizing the wrong instruments can lead to frustration and even cause harm to the components involved. Always ensure that the tools match the needs of the task.

| Common Mistake | Description | Consequences |

|---|---|---|

| Skipping Diagnostics | Not performing a thorough check beforehand | May lead to unnecessary replacements |

| Neglecting Safety Measures | Failing to take precautions | Increased risk of injury |

| Rushing the Process | Hurrying through the procedure | Higher chance of mistakes |

By being mindful of these common oversights, individuals can approach the component substitution process with greater confidence and efficiency.

Maintaining Your Water Pump After Installation

Ensuring optimal performance and durability requires regular upkeep and attention following the installation process. Proper maintenance not only extends the lifespan of the system but also enhances efficiency, ultimately saving time and resources. Adhering to a structured maintenance routine can prevent unexpected failures and costly repairs.

Routine Checks and Inspections

Regular monitoring of various components is crucial. Inspect for leaks, unusual noises, or vibrations that may indicate underlying issues. Periodic checks of the seals and connections can help identify wear and tear early on, allowing for timely intervention. Ensure that all mechanical parts remain well-lubricated and free from debris, which can impede functionality.

Cleaning and Servicing

Keeping the external components clean prevents dirt buildup, which can negatively affect performance. Schedule a professional service at least once a year to ensure that all internal mechanisms are functioning optimally. This includes checking the alignment of parts and replacing any worn components before they lead to major disruptions.

Q&A: Replacing a water pump

What is the role of coolant in a vehicle’s cooling system?

Coolant is a fluid that circulates through the cooling system to absorb heat from the engine and dissipate it through the radiator. It helps maintain optimal operating temperatures and prevents engine overheating.

How does a malfunctioning radiator affect the cooling system?

A malfunctioning radiator can lead to inadequate heat dissipation, causing the engine to overheat. This can result in engine damage if not addressed promptly, as the temperature gauge may indicate dangerously high levels.

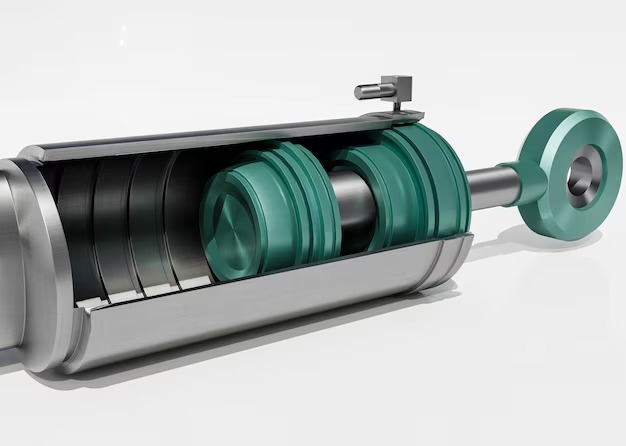

What is the purpose of the pulley in relation to the water pump?

The pulley is connected to the water pump and is driven by the engine’s serpentine belt. It helps to turn the water pump, which circulates coolant throughout the cooling system, maintaining proper engine temperature.

When should you replace the water pump in your vehicle?

You should replace the water pump if you notice signs of leakage, unusual noises, or if it fails during routine maintenance checks. It’s also advisable to replace it when changing the timing belt, as both components are often accessed simultaneously.

How does a faulty thermostat affect engine performance?

A faulty thermostat can cause the engine to either overheat or run too cool, disrupting the balance of the cooling system. This can lead to inefficient fuel consumption and potential engine damage if the temperature gauge indicates overheating.

What type of sealant is recommended for use with a water pump installation?

It is recommended to use a high-quality gasket sealant specifically designed for automotive applications when installing a water pump. This ensures a proper seal and prevents leaks between the water pump and engine block.

How can you identify engine damage caused by overheating?

Signs of engine damage from overheating include warped cylinder heads, cracked engine blocks, and blown head gaskets. A thorough inspection may be necessary if the temperature gauge has consistently shown high readings.

What are the consequences of ignoring coolant leaks?

Ignoring coolant leaks can lead to overheating, which may cause severe engine damage. Over time, low coolant levels can result in increased wear on engine components and potential failure of the cooling system.

How does the timing belt relate to the water pump replacement?

The timing belt is often located near the water pump, and when replacing it, it is advisable to replace the water pump as well. This prevents future labor costs since both components are accessible during the same service.

What role does the temperature gauge play in monitoring engine health?

The temperature gauge provides real-time feedback on the engine’s operating temperature. If it indicates overheating or fluctuates unexpectedly, it serves as an alert to check the cooling system for issues such as coolant leaks or radiator failure.

What are the signs of a failing water pump in a vehicle’s engine?

Signs of a failing water pump may include coolant leaking from the weep hole, unusual noises from the pump area, and engine overheating. If you notice any of these symptoms, it’s essential to inspect the water pump promptly.

How does a bad water pump affect the car’s cooling system?

A bad water pump can lead to inadequate circulation of coolant throughout the engine, causing the engine temperature to rise and potentially resulting in engine overheating. This can cause serious damage if not addressed quickly.

When should you consider changing the water pump in your vehicle?

You should consider changing the water pump when you notice signs of leakage, unusual noises, or if the coolant level is consistently low. Additionally, if you are replacing other components like the timing chain, it’s a good time to replace your water pump as well.

What is the process of replacing a vehicle’s water pump?

The process of replacing a vehicle’s water pump typically involves draining the coolant, removing the old water pump and its mounting hardware, installing the new pump with gasket material, and then refilling the cooling system with new coolant.

How can you access the water pump in your car?

To access the water pump, you usually need to remove components such as the radiator cap, serpentine belt, and possibly the timing cover, depending on your car’s make and model. Always refer to your repair manual for specific instructions.

Why is it important to refill the cooling system after changing a water pump?

It is important to refill the cooling system after changing a water pump to ensure that there is adequate coolant circulating through the engine. This helps prevent overheating and maintains proper engine temperature.

What role does the pump pulley play in the function of a car water pump?

The pump pulley connects to the belt-driven water pump and helps turn it, allowing it to circulate coolant throughout the engine. If the pump pulley is damaged or loose, it can lead to pump failure.

What are some common causes of a faulty water pump?

Common causes of a faulty water pump include wear and tear on the impeller, corrosion due to old coolant, and leakage from the water pump shaft or mounting. Regular maintenance can help identify these issues early.

How can you tell if coolant is leaking from the radiator or the water pump?

To determine if coolant is leaking from the radiator or the water pump, inspect for puddles under the vehicle. If coolant is leaking near the front of the engine and there’s a weep hole present on the water pump, it is likely from the pump.

What is the cost of replacing a bad water pump at an auto repair shop?

The cost of replacing a bad water pump at an auto repair shop can vary based on labor rates and the make and model of your vehicle. Typically, it can range from $300 to $800, including parts and labor for a replacement water pump.